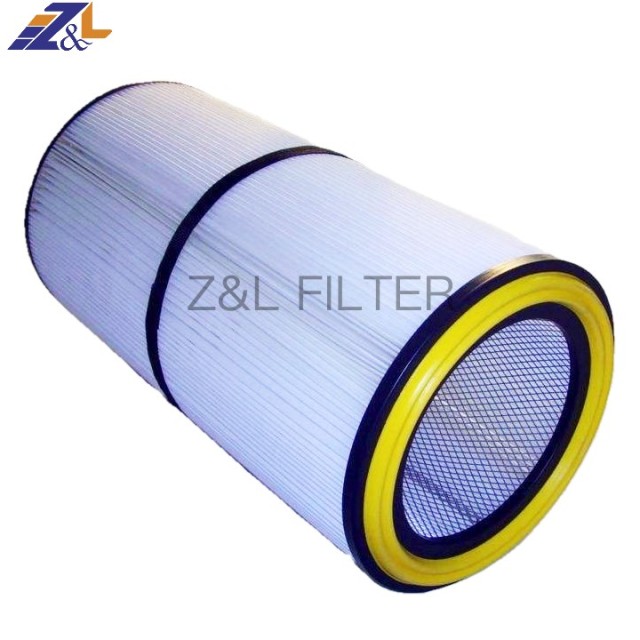

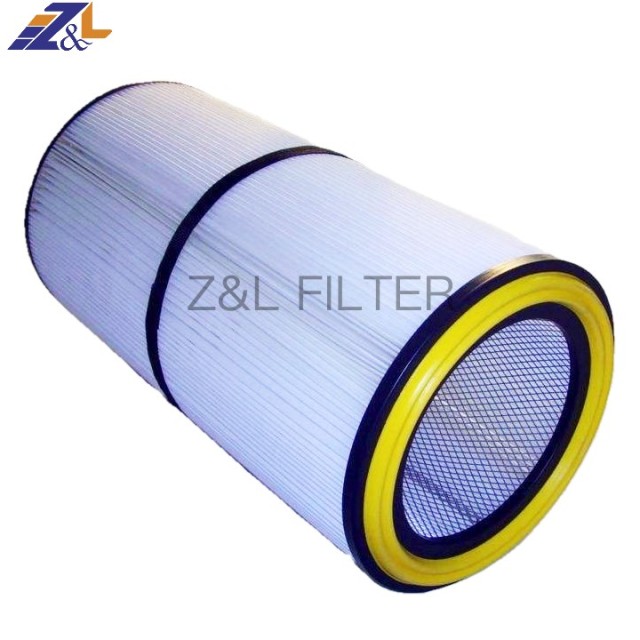

| dust collector air filter material | 1) Imported long fiber polyester filter media,fiber interwoven,evenly distributed. |

| 2) Filter material surface do waterproof and oil processing. | |

| 3) Good abrasion resistance,and the capability of withstand airflow pulse inverse blow is better than traditional filter media. | |

| 4) Smooth filter media surface,not sticky. | |

| 5) Excellent chemical resistance. | |

| 6) Good filter material stiffness,can be repeated washed. | |

| optional filter media | 1) Spunbonded polyester |

| 2) Polyester + Oil and water repellent | |

| 3) Polyester + PTFE Membrane (Coated by glue & Coated by heating) | |

| 4) Polyester + Anti-static (Aluminized antistatic & Polymer Antistatic ) | |

| 5) Polyester + Flame retardant | |

| 6) Polyester + Dual anti-treatment (Anti-static+Flame retardant, Oil and water repellent+ Anti-static, PTFE Membrane+ Anti-static) | |

| We will choose the most suitable filter media according to customers' requirement. | |

| caps/bottoms | hard eletro-galvanized steel /stainless steel |

| sealing gasket | rubber , |

| dust collector air filter parameters | 1) Operating temperature ≤ 135 ° C. |

| 2) Greatly increase the effective filtration area. | |

| 3) Ensure a low steady differential pressure, improve the circulation of air flow. | |

| 4) Small filter cartridge element, easy to install. | |

| 5) Especially suitable for large dust concentration industry. |

Product image:

| Hydraulic oil filters |

| Dseries:0030D series、 0035D series、 0055Dseries、0060Dseries、0075Dseries、0095Dseries、0110Dseries、0140Dseries、0160Dseries、0240Dseries、0280Dseries、0330Dseries、0500Dseries、0660Dseries、0990Dseries、 |

| RNseries:0040RNseries 、0063RNseries、0100RNseries、0160RNseries、0250RNseries、0400RNseries、0630R Nseries、0400DNseries |

| R series:0030Rseries、0060Rseries、0110Rseries、0160Rseries、0240Rseries、0330Rseries、0660Rseries、0850Rseries、0950Rseries、1300Rseries、1320Rseries、1700Rseries、26007Rseries |

| Air filters ,oil and air seaprators |

| Optional/alternative/replacement Donald air filters |

| Vocuum pump filters |

| Thermal power and nuclear power: steam turbine, boiler lubrication system, speed control system, fan and dust removal system purification. Machinery processing equipment: paper machinery, mining machinery and large precision machinery system of medium purification |