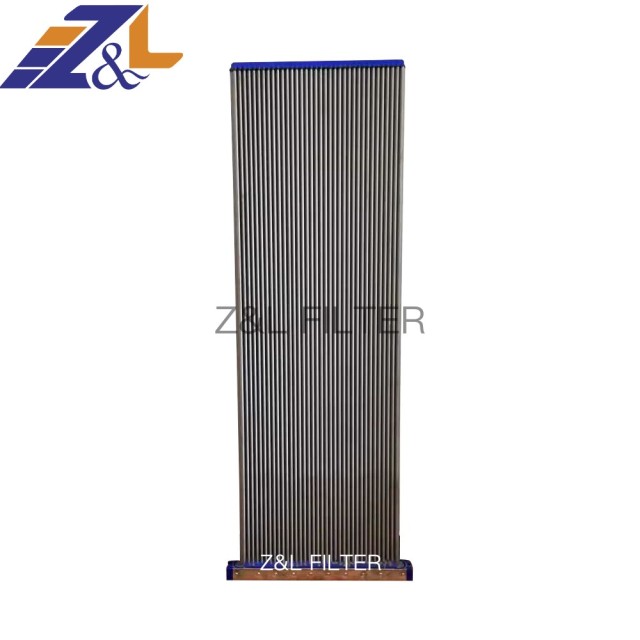

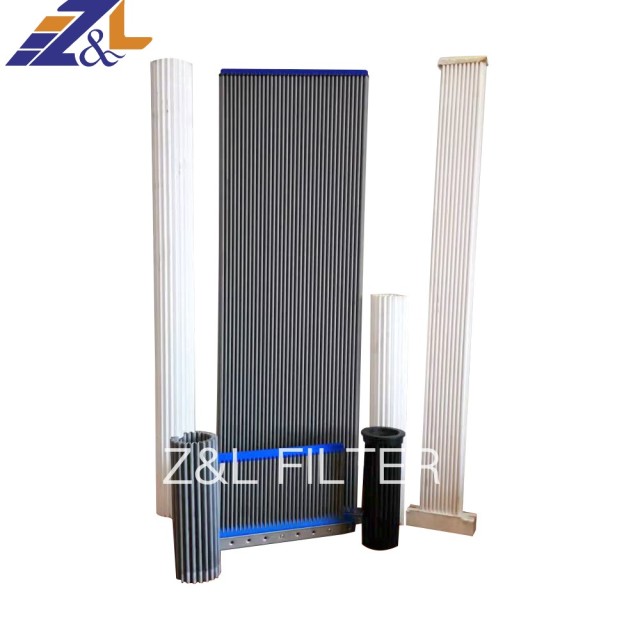

Product Introduction

Our factory is committed to the development and production of sintered filter , the use of German production technology, and repeated experiments, product details and materials to improve, so as to develop better performance, more reasonable structure, a larger filter area of dust sintered filter.

The moulds developed by our factory cooperate with the German production technology, forming a set of unique production process, greatly improve the production capacity, shorten the production period, for the product demand of customers, which can be on time to complete the production task with quality and quantity.

Product Application

(1) High dust capture rate: the sintered filter with micron filtration accuracy, 100% interception for above 1 um, generally the collection and dust removal efficiency can reach 99.99% for under 1 um

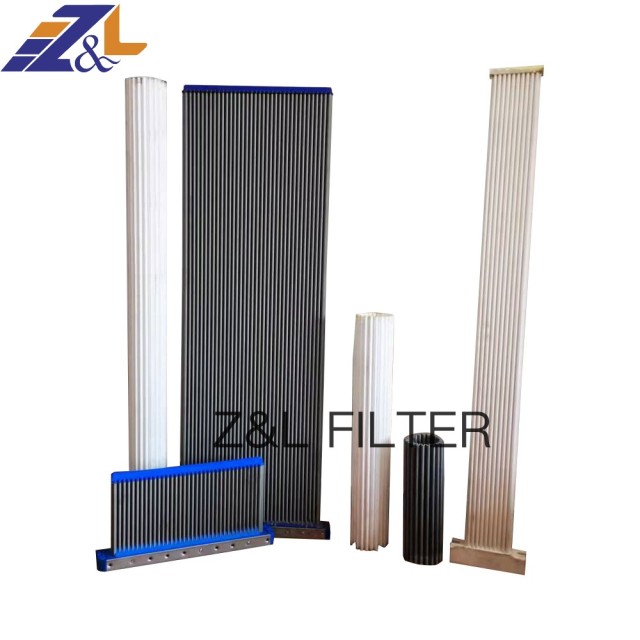

(2)Bigger filtration area:wavy design of surface, greatly reduces volums, and 3-6 times bigger filtration area than filter bags.

(3) Hydrophobic and oil-phobic: various polymer material with different densities are sintered into dust collector ,PTFE coating deeply into the substrate of siltered filter .ultra=fine hole resulting anti-viscosity mechanism ,with hydraophobic and oil repellent properties.

(4)acid /alkali resistance : special polyster materials ,could withstand strong acid and alkali ‘s long term corrosions.

(5)anti-blowing effect: PTFE coating without viscosity, which means little attachment to other sustances and smaller amount of blowback gas.dust removal effect perfect.

(6)shorter loss of pressure and stable resistance :with special coating,the dust passing through filter layers could be discharged directly without staying on the surface of filters .therefore ,the filtration layers would not be blocked after machines operations ,and during a long period ,air volume is little changeable with the time.

(7)longer service life : the high strength and toughness of the sintered filter ,could withstand repeated impact of high pressure gas during longer time .at the same time ,super acid and alkali resistance ability would let the filter’s service life reach more than 10 years.

Product application

(1) larger filtration area: each filter has 4 pleats in one hole ,others similar products only take 3 pleats ,which means the same type filer from our factory would update 30% filtration area ,such as z&l1500-9 ,surface volume is 4.7㎡,Other suppliers the same type ‘s surface volume only reaches 3.4㎡

(2)smaller resistance ,higher efficiency to filtrate: under the situation with the strength ,our sintered filter ‘s thickness could be 3mm,and stable thickness .this results our filtration area broader ,sharply improve the filtration efficiency

Product Application

(1) High dust capture rate: the sintered filter with micron filtration accuracy, 100% interception for above 1 um, generally the collection and dust removal efficiency can reach 99.99% for under 1 um

(2)Bigger filtration area:wavy design of surface, greatly reduces volums, and 3-6 times bigger filtration area than filter bags.

(3) Hydrophobic and oil-phobic: various polymer material with different densities are sintered into dust collector ,PTFE coating deeply into the substrate of siltered filter .ultra=fine hole resulting anti-viscosity mechanism ,with hydraophobic and oil repellent properties.

(4)acid /alkali resistance : special polyster materials ,could withstand strong acid and alkali ‘s long term corrosions.

(5)anti-blowing effect: PTFE coating without viscosity, which means little attachment to other sustances and smaller amount of blowback gas.dust removal effect perfect.

(6)shorter loss of pressure and stable resistance :with special coating,the dust passing through filter layers could be discharged directly without staying on the surface of filters .therefore ,the filtration layers would not be blocked after machines operations ,and during a long period ,air volume is little changeable with the time.

(7)longer service life : the high strength and toughness of the sintered filter ,could withstand repeated impact of high pressure gas during longer time .at the same time ,super acid and alkali resistance ability would let the filter’s service life reach more than 10 years.

Product application

(1) larger filtration area: each filter has 4 pleats in one hole ,others similar products only take 3 pleats ,which means the same type filer from our factory would update 30% filtration area ,such as z&l1500-9 ,surface volume is 4.7㎡,Other suppliers the same type ‘s surface volume only reaches 3.4㎡

(2)smaller resistance ,higher efficiency to filtrate: under the situation with the strength ,our sintered filter ‘s thickness could be 3mm,and stable thickness .this results our filtration area broader ,sharply improve the filtration efficiency

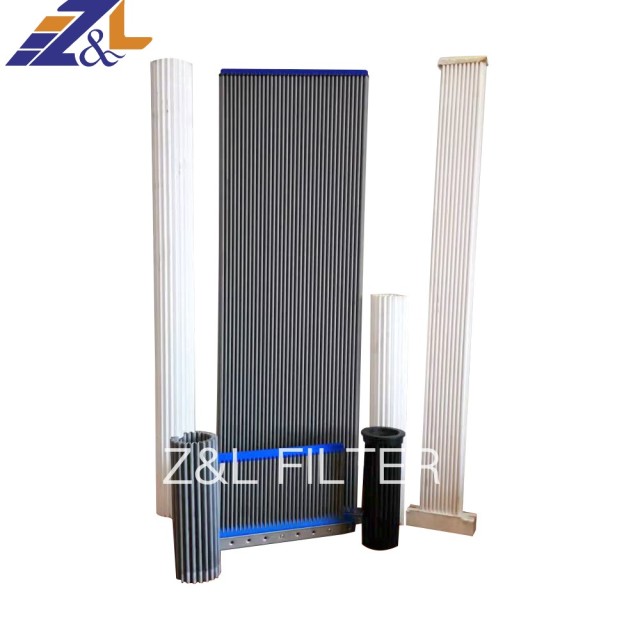

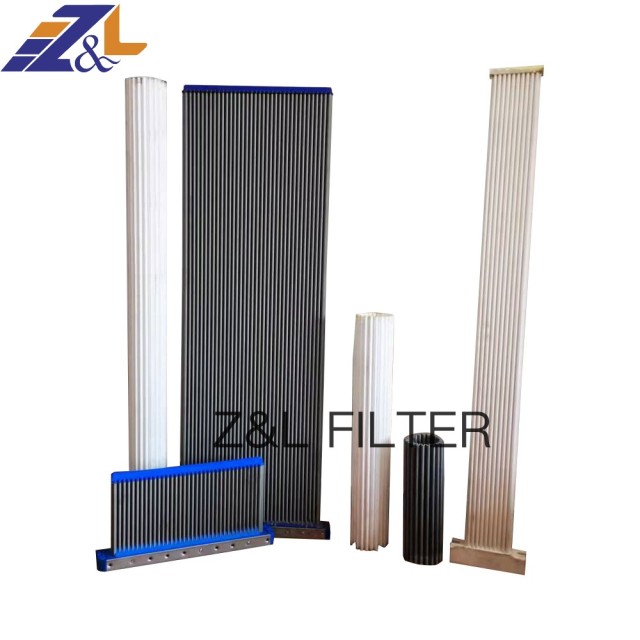

Related type of sintered filter introduction:

common type,

acid/alkali resisted type,

waterproof

electric-proof type,

Antistatic type

Similar type data sheet

| type |

L(MM) |

W1(MM) |

W2(MM) |

H1(MM) |

H2(MM) |

FILTRATION

AREA(㎡) |

| 1500-9 |

1500 |

565 |

480 |

78 |

50 |

4.7 |

| 1200-9 |

1200 |

565 |

480 |

78 |

50 |

3.8 |

| 755-9 |

755 |

565 |

480 |

78 |

50 |

2.3 |

| 1550-18 |

1550 |

1040 |

960 |

62 |

42 |

6.8 |

1550-18

(2.0) |

1550 |

1045 |

950 |

78 |

50 |

9.5 |

| 1200-18 |

1200 |

1045 |

950 |

78 |

50 |

7.6 |

| 755-18 |

755 |

1045 |

950 |

78 |

50 |

4.7 |

Our Service

Service Provide:

OEM ODM & OBM service, printing or logo information is acceptable.

Quality Guarantee:

All products have to pass strict inspection before they go out. If any problems caused by the product itself,

Our Service

Service Provide:

OEM ODM & OBM service, printing or logo information is acceptable.

Quality Guarantee:

All products have to pass strict inspection before they go out. If any problems caused by the product itself,

we will supply you the new replaced ones ASAP.

After-sales Service:

Any problems caused by using our products:

1) Keep the problem products and timely contact with us for better feedbacks.

2) Please do not damage problem products, if necessary, Send the

products and the attached oil and the coolant sample together to us for better analyzing

3) Attached with repair document, parts list, labor costs and any other materials which

can support a claim for compensation.

Some scens taken from factory:

Our clients around the Global

If any inquiry ,just contact us :